Electromagnetic Interferences (EMI): a significant issue for harsh environments

For sensitive missions in harsh environments to be accomplished optimally, it is essential to consider some parameters. For example, we can mention electromagnetic interference (EMI) that can disturb signal integrity and, therefore, sound transmission. To avoid it, it is necessary to choose micro-connectors using shielding.

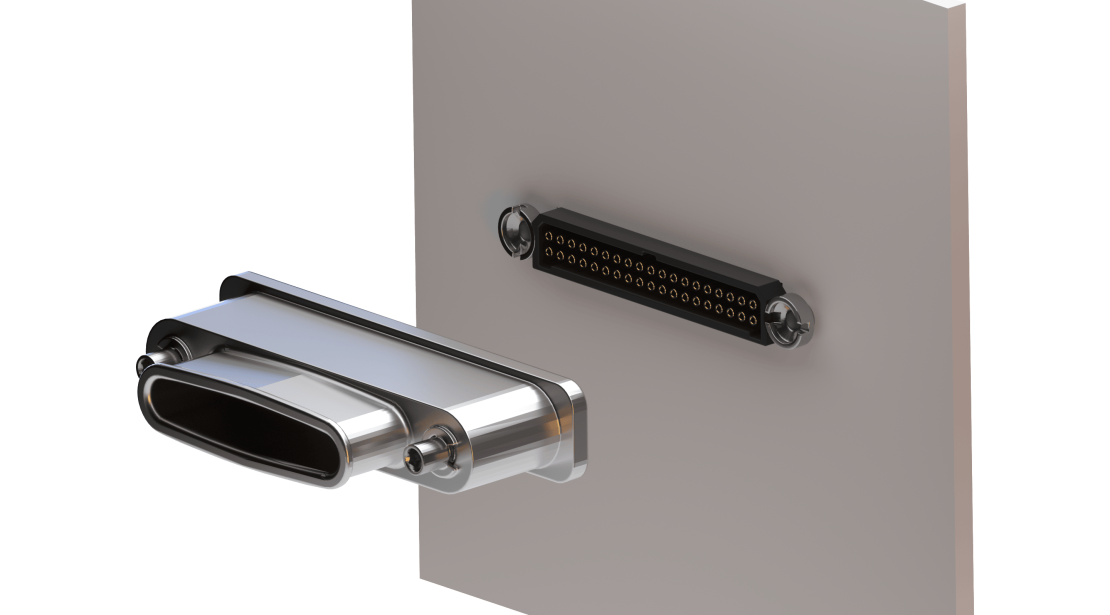

Overview of a reduced-size micro-connector

First, it is important to provide details about our range of EMM connectors, which belongs to the Nicomatic standard products catalog. They present the specificity of being given a 1.27 mm pitch, which allows 20% space-saving compared to a standard micro-D. Regarding the practicality that this product provides because of its reduced size and lightweight, we decided to bring touches of customization to meet specific needs.

Fixing the EMI issue with an EMM customized solution

To fix this problem, which can have severe consequences in applications such as space or the military, Nicomatic has created the EMM Panel Backshell to convert your 1.27 mm pitch connector into a 360° shielded panel solution.

Thus, it protects the connector couple from the panel to the braid. Furthermore, being compact and lightweight, it can perfectly meet the weight and size requirements of some applications such as satellites or UAVs.

Thanks to its ruggedness, it can integrate devices that will be used in extreme conditions, ensuring conductivity.

The customized EMM Panel Backshell configurations

Several configurations are available for the panel side and the backshell one.

Panel connectors can have 4 to 60 signal contacts and exist in male or female. For the PCB connectors, there is one version with straight-through contacts or SMT ones. You can also purchase a straight-on cable version of the connector.

Concerning the backshell side, you can also have it in male or female versions, and its contact number ranges from 14 to 60 contacts.

Key performance of the customized EMM Panel Backshell

We can first mention the fact that it meets the requirements of MIL-DTL-83513G and MIL-DTL-55302G standards. Then, its fixing hardware has been conceived to be mated and unmated a hundred times without performance deterioration. Concerning the connectors themselves, they are planned to withstand 500 plug-unplug cycles. Moreover, this configuration is certified to resist 20 g vibrations and can last 96 hours without being impacted by salt spray.

Thanks to its ruggedness, it can integrate devices that will be used in extreme conditions, ensuring conductivity.

The customized EMM Panel Backshell configurations

Several configurations are available for the panel side and the backshell one.

Panel connectors can have 4 to 60 signal contacts and exist in male or female. For the PCB connectors, there is one version with straight-through contacts or SMT ones. You can also purchase a straight-on cable version of the connector.

Concerning the backshell side, you can also have it in male or female versions, and its contact number ranges from 4 to 60 contacts.

Key performance of the customized EMM Panel Backshell

We can first mention the fact that it meets the requirements of MIL-DTL-83513G and MIL-DTL-55302G standards. Then, its fixing hardware has been conceived to be mated and unmated a hundred times without performance deterioration. Concerning the connectors themselves, they are planned to withstand 500 plug-unplug cycles. Moreover, this configuration is certified to resist 20 g vibrations and can last 96 hours without being impacted by salt spray.

Are you looking for a connection solution that can withstand such extreme conditions? Check out our EMM connectors and choose from hundreds of possible configurations.