In the demanding environment of embedded systems, poorly sized or unsuitable cabling can lead to critical malfunctions, including electromagnetic interference (EMI), mechanical failures, or signal loss, all of which impact the overall reliability of your applications. At Nicomatic, connectivity is our specialty, and our expertise extends far beyond connectors alone. We offer customized cabling services, specifically designed to meet the rigorous demands of your sector, from design to production.

Cabling tailored to your technical constraints

Every application has unique requirements: compatibility with extreme environments, reduced space, resistance to vibration, humidity, chemical agents, as well as adherence to industrial and military standards.

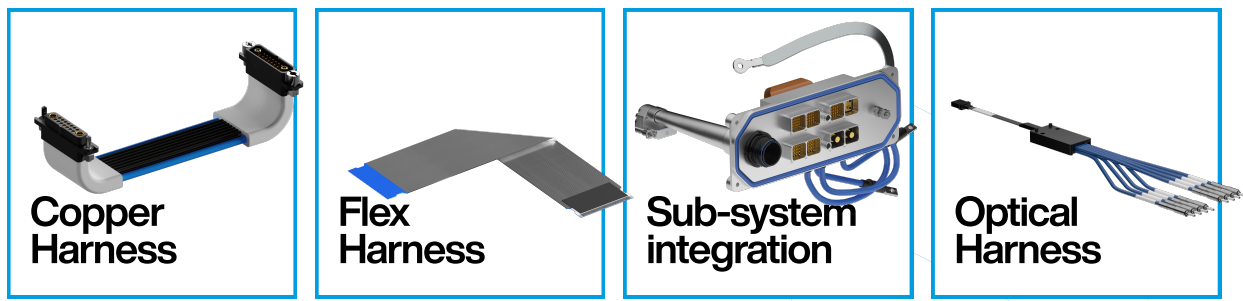

Our cabling solutions cover four key areas:

- Electrical (copper) harness: Copper electrical harness solutions integrating single wires, coaxial cables, and shielded pairs.

- Flex harness: Flexible assemblies, ideal for compact and dynamic applications.

- Sub-system integration: Complete integration solutions for complex systems, simplifying final assembly.

- Optical harness: VITA fiber optic harnesses optimized for high-speed data transmission and EMI resistance.

Our advanced technologies ensure increased protection and durability:

- Overmolding for resistance to shocks and mechanical stress.

- Backpotting for enhanced electrical insulation and optimal sealing.

- Customized marking (inkjet, laser, pad printing) for easy identification.

- Dedicated supply chain guaranteeing optimized production and delivery times.

Global expertise with five production sites

Our production capabilities span five global locations (France, India, Turkey, Sweden, United States), ensuring optimal proximity to our customers. This international presence allows us to address regional needs while complying with specific market regulations and safety requirements.

Certified quality and rigorous control

Our facilities are ISO 9001 and EN 9100 certified, ensuring production standards meet aerospace, defense, and space industry requirements. Furthermore, our cabling is manufactured according to IPC standards, guaranteeing optimal quality and reliability.

Each assembly undergoes rigorous internal testing, including:

- Electrical tests (continuity, insulation, contact resistance).

- Dimensional and visual inspections using binocular magnifiers.

- Mechanical tests evaluating connector and overmolding durability.

Our expertise is further reinforced by an in-house IPC-certified trainer, ensuring industry best practices for cabling and harness assembly.

A technical partner by your side

Our approach provides tailor-made solutions, reducing design errors and optimizing system performance. Partnering with Nicomatic delivers:

- Reduced overall costs through tailored initial design.

- Time savings via an optimized supply chain.

- Reduced technical risks thanks to certified expertise.

- Comprehensive support throughout your project, from the design phase to serial production.

Looking for cabling tailored to your technical requirements? Contact our experts to discuss your project and discover how our solutions can optimize your systems.