What are you looking for?

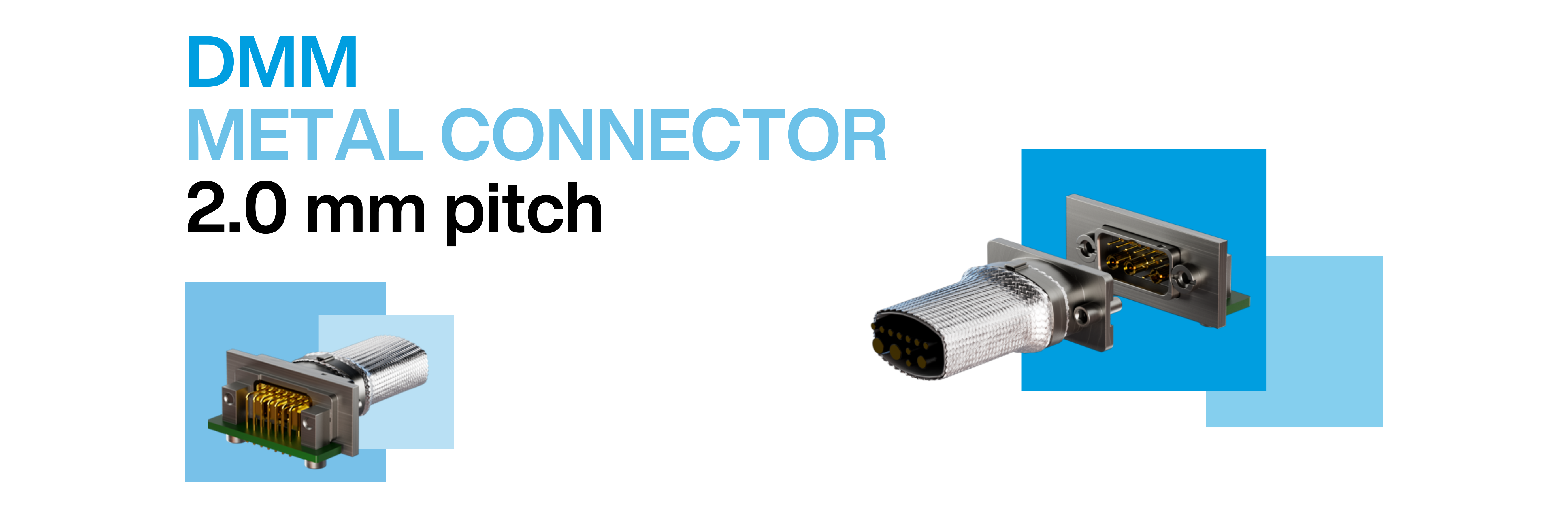

DMM connectors

Metallic connectors with a pitch of 2.0 mm

DMM METAL CONNECTOR - MICRO-D TYPE

High-Performance Metallic Connectors with a 2.0 mm Pitch

The DMM series connectors are highly durable and conform to MIL-DTL-83513G standards. Designed to optimize space while providing superior electromagnetic (EMI/RFI) and mechanical protection, these connectors are an ideal solution for demanding applications.

A backshell accessory can be added for 360-degree shielding. The DMM connectors also offer a wide variety of standard fixing options for secure mounting.

Key Benefits of DMM Connectors

- MIL-DTL-83513G compliant for high-reliability applications

- Compact, low-profile design with vibration resistance

- 360-degree EMI/RFI shielding

- Configurable from one to four rows of contacts

- Supports mixed contact types: High Power (HP), High Frequency (HF), and Low Frequency (LF)

- Up to 120 high-current contacts (3-5A) or 30 HP contacts (20-40A)

- Multiple termination options: push-wire, perpendicular PCB, angled PCB, Thru-Hole, and SMT

- Wire range:

- Signal contacts: 22 to 32 AWG

- Power and coaxial contacts: 12 to 20 AWG

DMM Series Overview

DMM-100 Series

- Up to 30 signal contacts

- Available terminations: wired, angled, straight to PCB, Thru-Hole, SMT

DMM-220 Series

- Supports mixed contacts: coax (HF), signal (LF), and high-current (HP)

- Two rows of signal contacts (each HP or HF contact replaces four LF contacts)

- Available terminations: crimped, angled, straight to PCB, Thru-Hole, SMT

DMM-320 Series

- Supports up to 40 signal contacts and 15 HP or HF contacts

- Coax frequency support: up to 6 GHz

- Available in three-row arrangements

- Customizable with mixed-contact configurations

DMM-420 & DMM-430 Series

- Four-row configurations, supporting up to 120 signal contacts

- Mixed contacts: coax (up to 6 GHz), signal (3-5A), high-current (20-40A)

- Flexible configurations: up to 30 (DMM-420) or 40 (DMM-430) COAX/HP contacts

- Even/odd arrangement for maximum customization

Start Configuring Your DMM Connector (Registration Required)

Build Your Perfect Connector

With 5M+ configurations available, you can create the best solution for your needs. Register on our website to generate a SKU, access drawings, and download models.

DMM Connectors: Designed for Compact Performance

We designed the DMM series to be more compact than traditional Micro-D solutions, providing high reliability without compromising on performance.

Superior Contact Technology

Nicomatic Signal (LF) Contacts

- Data transmission up to 5 Gbit/s in a 2 mm pitch connector

- Manufactured in-house for high precision and reliability

- Meets and exceeds MIL-DTL-83513G (tested up to 2500 cycles)

- Multi-lip stamped clip made of beryllium copper ensures stable electrical conductivity in harsh environments (vibration resistance: 20G, shock resistance: 100G)

Nicomatic High-Power (HP) Contacts

- Handles up to 30A

- Compact 4 mm pitch for high-density applications

- MIL-DTL-83513G compliant, tested for 500+ mating cycles

- Full derating data available for environmental specifications

Nicomatic High-Frequency (HF) Coaxial Contacts

- Frequency range: 400 MHz - 11 GHz

- Precision-turned for optimal signal integrity

- Designed in collaboration with European research laboratories

- Compatible with flexible and semi-rigid RF cables

Materials & Construction

Aluminum Shell

- Material: Machined from 6061 aluminum

- Finish: 20µ chemical nickel plating (resistant to 96-hour salt spray exposure)

- Lightweight & rugged for aerospace and military applications

PPS Insulator

- 30% glass fiber-reinforced PPS

- Excellent outgassing and low humidity absorption

- Compliant with high-altitude and space environments

- Modular tooling system allows rapid configuration changes

Fixing Hardware

- Available on both male and female sides

- Two types of fixings: racking and screw-locking

- Made of 316L stainless steel, passivated for salt spray resistance

- Compatible with various PCB and panel thicknesses

DMM Connector Configurations

PCB Mounting Options

Straight PCB

- Thru-Hole or SMT termination

- Compatible with 0.8 to 3.2 mm PCBs

- Mixed layouts supported

90° PCB

- Thru-Hole or SMT termination

- Compact design with racking/locked fixing hardware

- Mixed layout capability

Cabling Options

Pre-Wired & Custom Lengths

- Backpotting option available

- Metal braid and backshell options for EMI shielding

DMM Backshell Solutions

- Material: Aluminum 6061 with 20µ chemical nickel plating

- Provides mechanical protection and 360° EMI/RFI shielding (MIL-STD-1377)

- Compatible with Band-it type systems

Split Backshell

- Two-piece design for easy assembly and quick prototyping

Mono-Block Backshell

- Compact, single-piece construction

- Not compatible with low-profile shapes

- Assembled using circlip tooling C17596

Why Choose Nicomatic DMM Connectors?

- Compact & Rugged: Saves space without sacrificing durability

- Customizable: Wide range of configurations to fit your exact needs

- Superior EMI/RFI Protection: 360-degree shielding ensures signal integrity

- Proven Reliability: Meets and exceeds MIL-DTL-83513G standards

Ready to build your perfect connector? Click below to configure your DMM connector, access drawings, and download 3D models.

Start Configuring Your DMM Connector (Registration Required)

Backshell protection

Connectors and wiring solutions

Questions / Answers

What types of power connectors does Nicomatic offer?

How to choose the Power connector for my application?

What standards do the Nicomatic power connectors meet?

What is the average shelf life of a Nicomatic power connector?

Can you customize power connectors for certain needs?

What are the normal delivery times for your power connectors?

How can I get a quote for a large quantity of power connectors?

What payment methods are accepted for purchasing power connectors?

What is a single contact (signal)?

What is HF contact?

What is the HP touch?

What is EMI?

What is RFI?

What is EMI/RFI protection?

What is COAX contact?

How do you choose a connector according to frequency (HZ) and impedance (Impedance-Ω)?

When to choose a plastic connector and when to choose a metal connector?

What is the advantage of SMT contacts (Surface Mount Technology) compared to intrusive contacts on the PCB?

Golden advice for designing connectors on a PCB board