In demanding environments such as aerospace, defense, or industrial sectors, every connection matters. Yet, connector assembly often remains a source of frustration and risk:

- Lost screws in the field, often impossible to retrieve in confined or critical spaces, delaying operations and increasing maintenance costs.

- Misalignment during installation, leading to damaged contacts, degraded performance, or even mission-critical failures.

- Time-consuming and tedious assembly, with repetitive handling that slows teams down and increases the risk of error.

- Foreign Object Damage (FOD) risks, where even a single dropped screw can damage sensitive equipment.

👉 These challenges are not inevitable. With Nicomatic’s Captive Screw, you benefit from a smart and optimized solution, designed to save time and enhance connection security.

Technology Designed for Efficiency

✔ Secure fastening with the "Mate-before-lock" system

The concept is simple: the connector is positioned before being locked in place, ensuring perfect alignment and preventing insertion errors that could damage contacts. This significantly reduces the risk of bad connections or failures due to improper assembly.

✔ Captive screw system: no more lost parts, no more FOD risk

Thanks to its captive mechanism, the screw remains attached to the connector even when fully unscrewed. That means no lost components and, most importantly, reduced risk of Foreign Object Damage (FOD)—a critical concern in aerospace and industrial applications where a single loose screw can lead to serious consequences.

✔ Simplified installation for faster maintenance

With an ergonomic design, this system enables smooth and efficient assembly and disassembly, while ensuring secure fastening even in tough conditions. The result? Faster, more precise installation and maintenance.

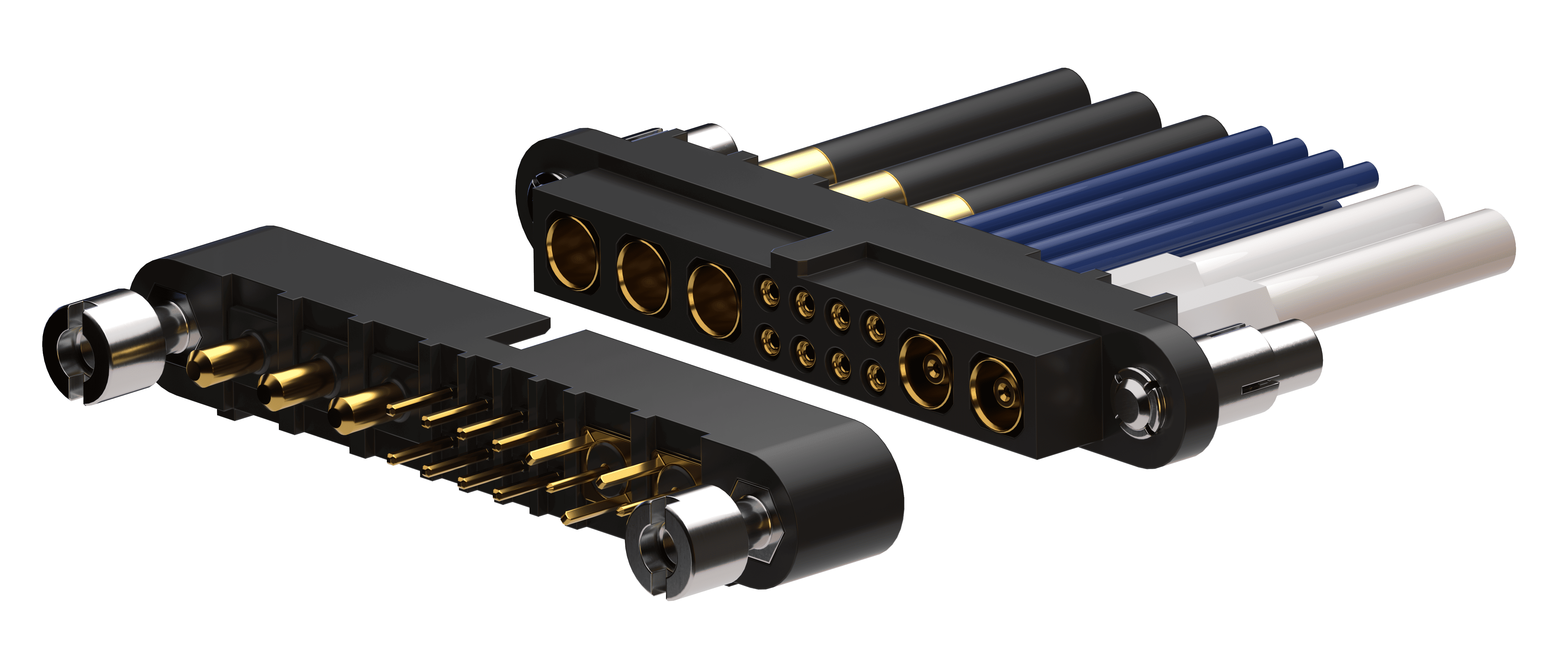

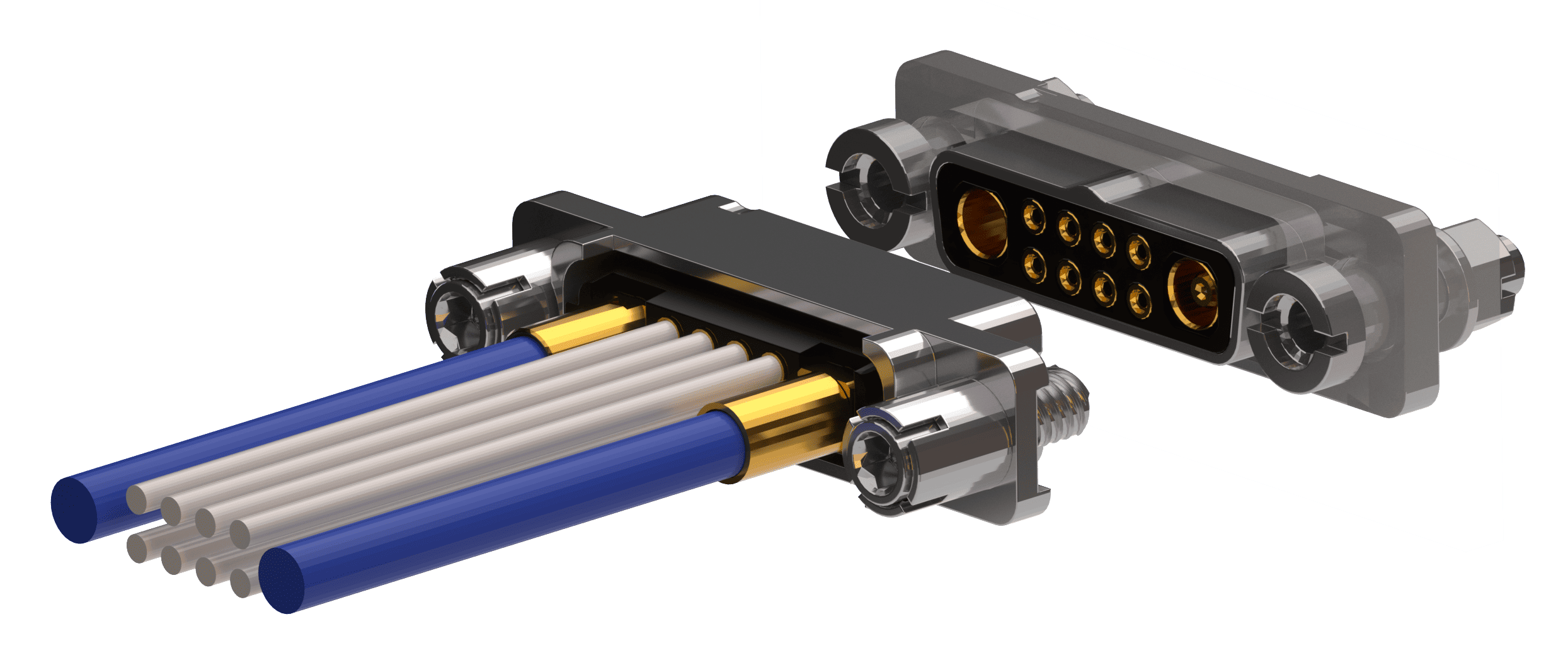

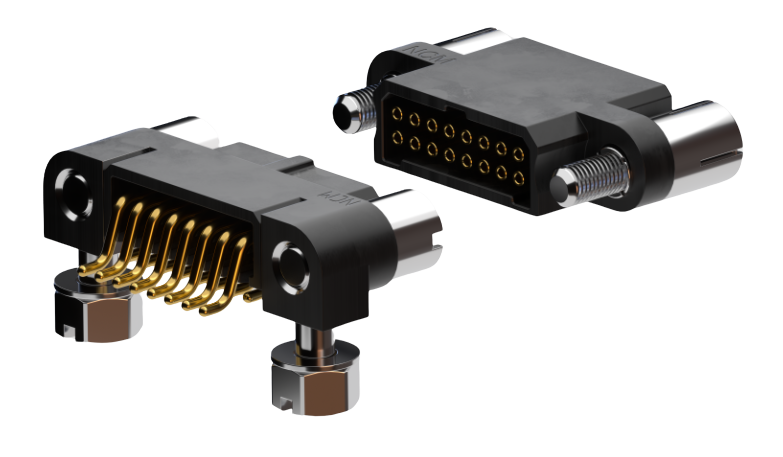

Available for Your CMM, DMM & EMM Connectors

At Nicomatic, we designed the Captive Screw to be fully compatible with our main high-performance connector ranges: CMM, DMM, and EMM.

The Captive Screw is tailored to your needs and available in three versions: M16C, D53C, and E02.

✔ CMM → M16C fastener: High-density modular connectors designed for compact, reliable applications

✔ DMM → D53C fastener: Rugged connectors for harsh environments, offering maximum modularity.

✔ EMM → E02 fastener: Ultra-miniature, high-performance solution ideal for embedded applications with extreme resistance to vibration and shock.

With the Captive Screw, these connectors benefit from an optimized fastening system that simplifies assembly while ensuring a secure, long-lasting connection.

Engineered for Demanding Environments

Critical environments—exposed to intense vibration, strong shocks, or extreme conditions—require fastening solutions that ensure a stable and reliable connection under any circumstance.

🔹 Vibration resistance: tested from 10 to 2000 Hz on three axes, with no signal interruption (>1 µs).

- 10g for CMM

- 10 to 15g for DMM

- Up to 45g for EMM

🔹 Shock resistance: maintains reliable connections in all conditions.

- Up to 100g for 6 ms for DMM and CMM

- Up to 160g for 6 ms for EMM

🔹 Extreme condition resistance: guaranteed operation from -55°C to +125°C, compliant with lead-free reflow profiles.

🔹 Chemical compatibility:

- MIL-DTL-83513 compliant (DMM & EMM), ensuring resistance to industrial and aerospace fluids.

- MIL-DTL-55302F compliant (CMM), ensuring high reliability for military and industrial use.

🔹 Corrosion protection: salt spray tested for 96 hours with 5% NaCl, ensuring optimal resistance in aggressive environments.

Choose a Smart and Durable Fastening Solution

With Nicomatic’s Captive Screw, you can secure your connections with ease. Designed to prevent assembly errors, speed up installation, and ensure maximum reliability, it’s the ideal solution for demanding environments.

- Fewer risks, more efficiency

- Robust connections, even in extreme conditions

- Optimized assembly to save time

Need more information? Contact us!